Summary

- Hydraulic fracturing is a technology

- Can by used in many different ways

- Used since 1947 to create small cracks

- To speed flow in conventional wells

- Now being used on vast scale for shale

- 1000 times size of conventional fracs

- Cracks extend hundreds of feet from well

- Huge amounts of water, chemicals and sand

- Energy of small nuclear bomb used

- Symptomatic of wider issues

- Massive intensification of extraction

Hydraulic Fracturing (Fracking) is a general technology, like for instance explosives, that can be used in many ways. In fact prior to the advent of hydraulic fracturing explosives were sometimes used to fracture oil wells (e.g. a string of sticks of dynamite lowered down well). However technologies can be used in a lot of different ways and just because a technology isn’t horrifically bad if used on a small scale does not mean that its effects when used on a much larger scale will not be much worse. Going back to the example of explosives, blowing up a few rocks in a small quarry is one thing but using amounts of explosives each week equivalent to the atomic bomb dropped on Hiroshima, as is done by companies involved in mountaintop removal coal mining (another extreme energy method) in the Appalachian Mountains in the Eastern US is not remotely comparable.

However promoters of fracking for shale gas often trot out the argument that because hydraulic fracturing has been used to some extent since 1947 there cannot be anything to worry about (e.g. Cuadrilla say in evidence to a parlimentary committee that ‘hydraulic fracture stimulation … have been used across the oil and gas industry (including previously in the UK) for many decades’). This is technically true but it is also an absolutely ridiculous comparison. Comparing the first (1000 US gallons) hydraulic fracturing treatment in 1947 to what happens on a modern day frac-pad exploiting the Marcellus Shale in Pennsylvania, which can use up to 50 million US gallons of fracking fluid, is like comparing setting off a firework with dropping a nuclear bomb on a city. The most basic mechanism is similar (though there are lots of differences) but the effects of the second are a little more severe. See the table below for comparisons of the volumes of hydraulic fracturing fluid used in fracking over the last 60 years.

| Year | Summary | Location | Company | Volume (US gal.) | Fluid |

|

Conventional

|

|||||

| 1947 | First hydraulic frac | Kansas | Stanolind Oil | 1,000 | Napalm |

| 1949 | First commercial frac | Oklahoma | Halliburton Oil Well Cementing Company | 1,000 | Crude Oil and Gasoline |

| 1957 | Typical frac | Texas | Continental Oil | 10,000 | Diesel oil |

| 1974 | Typical frac | Colorado | Amoco | 50,000 | Polymer emulsion |

| 1988 | Typical frac | Oklahoma | Amoco | 60,000 | Carbon dioxide foam |

|

Unconventional (Shale)

|

|||||

| 1986 | First massive hydraulic gel frac | Texas | Mitchell Energy | 400,000 | Cross-linked gel |

| 1997 | First slickwater hydraulic frac | Texas | Mitchell Energy | 800,000 | Slickwater |

| 2008 | Typical horizontal Barnett Shale frac | Texas | Devon energy | 3,500,000 | Slickwater |

| 2010 | Typical horizontal Marcellus Shale frac | Pennsylvania | Chesapeake Energy | 5,500,000 | Slickwater |

| 2011 | 10 well frac-pad | Pennsylvania | Consol Energy | 47,000,000 | Slickwater |

Table comparing the evolution in the size of hydraulic fracturing treatments over the last 60 years (see Hydraulic Fracturing: History of AN ENDURING TECHNOLOGY for some of the early history and see Oil Shale Gas: Marcellus Shale and Shale Gas Wiki: Amount of Water Used for more recent developments)

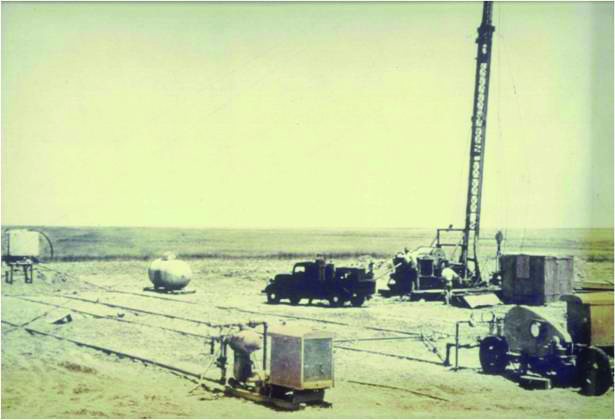

While the details are not particularly important it can be seen that the size of a typical hydraulic fracturing treatment on a conventional oil or gas well (which are only used on some wells) has grown by around a factor of 60 since fracking was first used in the late 1940s. This in part reflects the increasing difficultly in producing oil and gas and desperation involved. The other major point to notice is that even the modern day fracking of conventional wells pales into insignificance compared to the fracking treatments used to extract shale gas over the last few years. The initial tests in the Barnett Shale in the 1980’s were using fracking treatments an order of magnitude larger that typical fracking of conventional wells and this had risen to almost 100 times larger by the time serious commercial production began less than a decade ago. The huge multi-well pads (10 or more wells per pad) that are now becoming common in shale gas exploitation involve another order of magnitude again concentrating the equivalent of 1000 conventional fracking treatments into a small area. Comparing photographs of the first fracking test in 1947 with those of a modern fracking pad in the US gives some idea of the increased intensity of operations.

Photographs comparing of the first hydraulic fracturing operation in 1947 with a modern shale gas frac-pad

The volume of the fracking fluid used is but one aspect of the treatment however and in reality the intensity of shale gas fracking operations are even higher that just comparing fluid volumes would suggest. The pressures used in fracking treatments have also risen and it is now not uncommon for pressures of 15,000 pounds per square inch (psi) to be used in modern shale gas fracking (around the pressure at the bottom of the Marianas Trench, the deepest part of the worlds oceans, almost 7 miles below sea level). Given these sorts of pressures along with the volumes of fluid involved (10 olympic swimming pools worth per well) a question that springs to mind is how much energy is involved. The answer: a 10 well frac-pad is equivalent to a 4.4 kiloton nuclear bomb going off underground. When you realise this it is not at all surprising that these operations are resulting in numerous earthquakes. Chemically, fracking has also intensified enormously. While the gelled petroleum products initially used were certainly quite toxic they were at least relatively simple, with few ingredients. Modern slickwater fracking in contrast usually involves a whole cocktail of products most of which are made up of many ingredients. The fracking industry in the US is believed to use over 2500 fracking products that contain over 750 different chemicals including breakers, corrosion inhibitors, crosslinkers, gels, oxygen scavengers, pH adjusting agents, scale inhibitors and surfactants. The shear number of different chemicals involved combined with the huge fluid volumes makes problems with toxicity pretty much inevitable.

Finally the amount that fracking has actually been used has changed vastly over the last 60 years. At first fracking was only used on a limited set of marginal wells where the extra simulation could increase production rates to an economic level. The fraction of conventional wells that recieve some sort of fracking treatment has certainly increase over time, particularly for natural gas wells, again in part reflecting an increased difficultly in extracting these fossil fuels. The introduction of shale gas extraction however has introduced a class of wells where all of them are fracked. Due to the nature of shale gas extraction, where wells have to coat an area in order to extract the gas, the number of wells drilled is also much higher than for conventional gas. It is also the case that with shale gas extraction, there is a much higher likelihood that wells will be re-fractured several times over their short lifetimes, to try to prop up production until they are abandoned. The combination of these effects has resulted in an explosion in the amount of hydraulic fracturing over the last decade with the global market growing by almost a factor of five. The combination of the massive growth in both the amount and intensity of hydraulic fracturing treatments is increasing its impacts enormously. This video of a shale gas fracking operation in the US gives some idea of what the impact of just the process itself can have on a community.